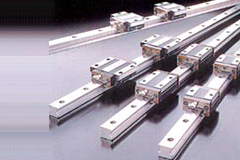

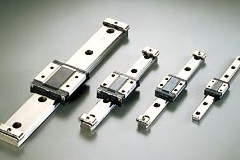

SSR

The compact design with a low sectional height and the ball contact structure at 90°

in the radial direction make this model an optimal model for horizontal guide units.

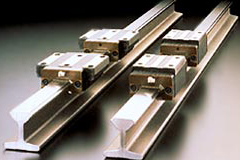

SNR/SNS

SNR:A radial type LM Guide with the highest rigidity among the Caged Ball LM Guide series.

SNS:A four-way equal load LM Guide with the highest rigidity among the Caged Ball LM Guide series.

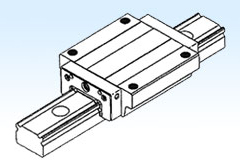

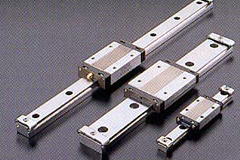

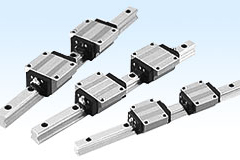

SHS

Since each row of balls is arranged at a contact angle of 45°,this model can be used in all directions.

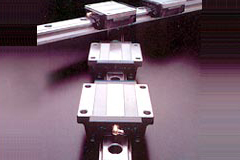

SHW

Since its LM rail has a wide structure with a low center of gravity,

this 4/way equal load LM Guide achieves a high Mc moment.

SRS

Since its LM rail has a low sectional height, this LM Guide achieves a lightweight and compact structure.

SRG

An ultra-heavy load Roller Guide with a rigidity twice that of our full-ball type LM Guide. It has global standard dimensions and achieves long-term maintenance-free operation.

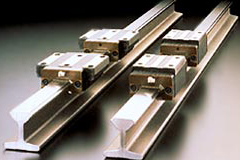

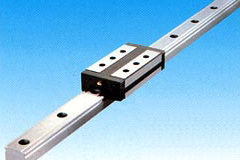

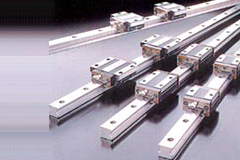

SR

Since it is a compactly designed model that has a low sectional height and a ball contact structure capable of receiving a large load in the radial direction, this LM Guide is optimal for horizontal guide units.

NR/NRS

NR:This model is an ultra-heavy type of LM Guide that achieves a deep

grooved raceway with its diameter more approximate to the ball diameter

than the conventional type and has high rigidity, vibration and shock

resistance, and damping characteristics, which are required for machine

tools. As a result, it is optimal for receiving a radial load in particular.

NRS:This model is an ultra-heavy type of LM Guide that achieves a deep

grooved raceway with its diameter more approximate to the ball diameter

than the conventional type and has high rigidity, vibration and shock

resistance, and damping characteristics, which are required for machine

tools.

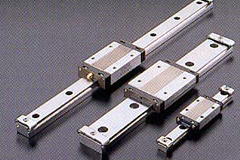

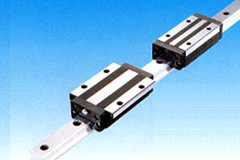

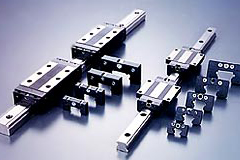

HSR

A global standard size LM Guide in which each row of balls is placed at a

contact angle of 45° so that the rated loads applied to the LM block are

uniform in the four directions (radial, reverse radial and lateral directions),

enabling the LM Guide to be used in all orientations.

HSR-YR

When using two units of LM Guide facing each other, the previous

model required much time in machining the table and had difficulty

achieving the desired accuracy and adjusting the clearance. Since

model HSR-M1YR has tapped holes on the side of the LM block.

a sampler structure is gained and significant man-hour cutting and

accuracy increase can be achieved.

JR

Since its LM rail has a sectional shape with high flexural rigidity, this LM

Guide can be used as a structural member.

CSR

This model is an integral type of LM Guide that squares an internal

structure similar to model HSR, which has a proven track record and

is highly reliable, with another and uses two LM rails in combination.

HRW

Due to a low center-of-gravity structure with a large rail width and a low

overall height, this LM Guide model can be used in places where space

saving is required or high rigidity against a moment is required even with

a single rail.

GSR/GSR-R

GSR:Since this LM Guide model has a large self-adjustment capability, it is

optimal for locations where it is difficult to secure mounting accuracy and

for general industrial machines and the likes.

GSR-R:Since the thrust load on the pinion shaft can be kept low due to

rack-pinion meshing, it is easy to design systems with pinion shaft

bearings and tables that are not so rigid.

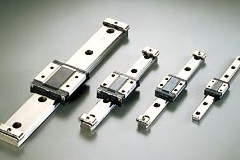

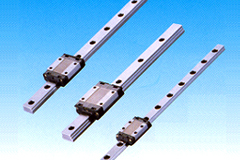

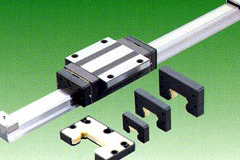

RSR/RSR-W

These models are Miniature LM Guides capable of receiving loads

in all directions, and adequately operating under a small moment

load despite being single-rail guides.

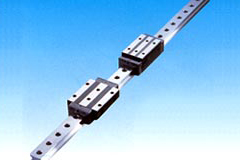

RSR-Z

This model is a Miniature LM Guide that achieves weight-saving and a

low cost by using a resin material in part of the LM block.

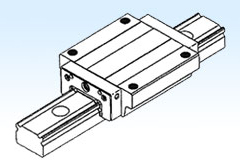

RSH/RSH-Z

This model is a Miniature LM Guide equipped with a ball retainer in the

LM block.

HCR

An LM Guide capable of performing larger circular motion than rotary

bearings.

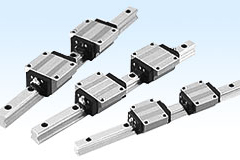

HSR...M2

Balls roll in four rows of raceways precision-ground on an LM rail

and an LM black, and endplates incorporated in the LM block allow the

balls to circulate. Each row of balls is placed at a contact angle of 45˚

so the rated loads applied to the LM block are uniform in the four

directions(radial, reverse radial and lateral directions), enabling the LM

Guide to be used in all orientations.

HSR...M1

Balls roll in four rows of raceways precision-ground on an LM rail

and an LM black, and endplates incorporated in the LM block allow the

balls to circulate. Each row of balls is placed at a contact angle of 45˚

so the rated loads applied to the LM block are uniform in the four

directions(radial, reverse radial and lateral directions), enabling the LM

Guide to be used in all orientations. The high temperature type LM

Guide is capable of being used at service temperature up to 150℃.

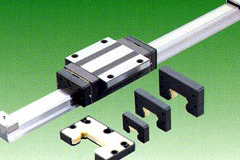

QZ

QZ Lubricator feeds the right amount of lubricant to the raceway on the LM

rail. This allows an oil film to continuously be formed between the rolling

element and the raceway, and drastically extends the lubrication and

maintenance intervals. The structure of QZ Lubricator consists of three

major components:

(1) a heavy oil-impregnated fiber net (function to store

lubricant).

(2) a high-density fiber net(function to apply lubricant to the

raceway) and

(3) an ail-control plate (function to adjust oil flow). The

lubricant contained in QZ Lubricator is fed by the capillary phenomenon,

which is used also in felt pens and many other products, as the

fundamental principle.

LaCS

LaCS removes minute foreign material adhering to the LM rail in multiple stages and prevents it from entering the LM block with laminated contact structure (3-layer scraper).

|